|

|

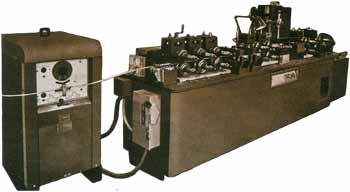

Tube mill (Made in USA)

High temperature corrosion resistant Nickel based alloy tubes such as Incoloy, Inconel and various grades of stainless steel (S.S) tubes are manufactured by means of most mordern tube forming and welding mill, imported from USA.

FEATURES

- Clean inner surfaces free from drawing compounds.

- Close

tolerances on diameter and wall thickness.

- Small

tolerances on ovality.

- Smooth

surfaces.

- Uniform

meterial thickness.

EDDY CURRENT TESTING

With a view to ensure uniform and perfect welding of the tubes even before the tubes come out of the tube mill, they are tested by Eddy Current. The Eddy Current testing Unit is connected to the tube lengths whenever the weld is defective, the defective tube lengths are automatically cut off. Thus the "ELECTRONIC EYE" not only ensures the quality of the weld but also highlights defects if any in the raw meterials thereby avoiding human errors and ensuring a perfect quality of the final product i.e.tubes.

APPLICATIONS

Because

of the versatility of the Nickel based alloys and Chrome Nickel Steel alloys,

the tubes made from these alloys have a very extensive use in the industries,

list of which goes on increasing every day. Some of the industries where they

are widely used are as under:

- Aircraft

- Atomic Energy Establishments

- Chemicals and Fertilizers

- Dairies, Breweries, distilleries and sugar mills

- Electrical Heating Elements

- Glass

- Heat Exchanegers

- Pulp and Paper

- Pharmaceuticals

- Petrochemicals

-

Textiles

PRODUCT

INFORMATION

|

OUTSIDE

DIAMETER

|

WALL

THICKNESS

|

|||||||||

|

Inch

|

mm

|

mm

0.40

Inch 0.016" |

0.50

0.020" |

0.60

0.024" |

0.70

0.028" |

0.80

0.032" |

0.90

0.036" |

1.00

0.040" |

1.20

0.048" |

1.60

0.064" |

|

9/32

|

7.15

|

N/S

|

S

|

-

|

-

|

--

|

-

|

-

|

-

|

|

|

5/16

|

8.0

|

N/S

|

S

|

S

|

-

|

-

|

-

|

-

|

-

|

-

|

|

3/8

|

9.5

|

-

|

S

|

S

|

S

|

N/S

|

N/S

|

-

|

-

|

-

|

|

25/64

|

10.0

|

-

|

N/S

|

S

|

S

|

N/S

|

N/S

|

-

|

-

|

-

|

|

7/16

|

11.1

|

-

|

-

|

N/S

|

S

|

N/S

|

N/S

|

-

|

-

|

-

|

|

1/2

|

12.7

|

-

|

-

|

N/S

|

S

|

N/S

|

N/S

|

-

|

-

|

-

|

|

5/8

|

15.87

|

-

|

-

|

-

|

S

|

N/S

|

N/S

|

N/S

|

-

|

-

|

|

41/64

|

16.0

|

-

|

-

|

-

|

S

|

N/S

|

N/S

|

N/S

|

-

|

-

|

|

3/4

|

19.0

|

-

|

-

|

-

|

S

|

N/S

|

N/S

|

S

|

N/S

|

N/S

|

|

1

|

25.4

|

-

|

-

|

-

|

N/S

|

N/S

|

N/S

|

S

|

S

|

S

|

|

1-1/4

|

31.8

|

-

|

-

|

-

|

N/S

|

N/S

|

N/S

|

S

|

S

|

S

|

|

S-Standard

Sizes

|

N/S-Non-Standard

Sizes

|

|||||||||

|

Comparative

Properties of

Materials

|

|||||||||

|

Grade

TP |

C

max. |

Mn.

max. |

P

max. |

S

max. |

Si

max. |

Ni

|

Cr

|

Mo

|

Ti

|

|

304

|

0.080

|

2.00

|

0.040

|

0.030

|

0.75

|

8.00-11.00

|

18.00-20.00

|

-

|

-

|

|

304L

|

0.035

|

2.00

|

0.040

|

0.030

|

0.75

|

8.00-13.00

|

18.00-20.00

|

-

|

-

|

|

310

|

0.150

|

2.00

|

0.040

|

0.030

|

0.75

|

19.00-22.00

|

24.00-26.00

|

-

|

-

|

|

316

|

0.080

|

2.00

|

0.040

|

0.030

|

0.75

|

10.00-14.00

|

16.00-18.00

|

2.00-3.00

|

-

|

|

316L

|

0.035

|

2.00

|

0.040

|

0.030

|

0.75

|

10.00-15.00

|

16.00-18.00

|

2.00-3.00

|

-

|

|

316

Ti

|

0.080

|

2.00

|

0.040

|

0.030

|

1.00

|

11.00-14.00

|

16.05-18.05

|

2.25-3.00

|

5xC

min

|

|

321

|

0.080

|

2.00

|

0.040

|

0.030

|

0.75

|

9.00-13.00

|

17.00-19.00

|

-

|

5xC

min

|

|

430

|

0.120

|

1.00

|

0.040

|

0.030

|

0.75

|

-

|

16.50-18.00

|

-

|

6xC%

~ 0.75

|

|

409

|

0.080

|

1.00

|

0.045

|

0.045

|

1.00

|

0.50

|

10.50-11.75

|

-

|

-

|

|

Physical

Properties

|

|||||||

|

Grade

TP |

Tensile

Strength ksi (MPa) |

Yield

Strength ksi (MPa) |

Enlongation

in 2 inches%min |

Max.

Hardness

|

Thermal

conductivity Cal/Sec. Cm. °C. at Temp. range 20-500 °C |

Co-eeficient

of expansion x 106 Cm/Cm./°C

at Temp. range 20-870 °C

|

|

|

Brinnel

|

Rockwell

|

||||||

|

304

|

75(515)

|

30(205)

|

35

|

192

|

B

90

|

0.051

|

19.8

|

|

304L

|

70(485)

|

25(170)

|

35

|

192

|

B

90

|

0.051

|

19.8

|

|

310

|

75(515)

|

30(205)

|

35

|

192

|

B

90

|

0.044

|

18.8

|

|

316

|

75(515)

|

30(205)

|

35

|

192

|

B

90

|

0.042

|

19.3

|

|

316L

|

70(485)

|

25(170)

|

35

|

192

|

B

90

|

0.042

|

19.3

|

|

316

Ti

|

70(540)

|

30(205)

|

35

|

192

|

B

90

|

0.042

|

19.3

|

|

321

|

75(515)

|

30(205)

|

35

|

192

|

B

90

|

0.051

|

19.8

|

|

430

|

60(414)

|

35(241)

|

20

|

190

|

B

90

|

-

|

-

|

|

409

|

60(414)

|

30(207)

|

20

|

207

|

B

95

|

-

|

-

|

|

Stainless

Steel Tube Manufacturing Programme

|

||||||||||||

|

Wall

thickness

in mm |

0.5

|

0.6

|

0.7

|

0.8

|

1.0

|

1.2

|

1.6

|

2.0

|

2.6

|

3.0

|

3.2

|

3.6

|

|

O.D.

in mm |

Weight

in Kg/metre

|

|||||||||||

|

6.0

|

0.069

|

0.081

|

0.093

|

0.104

|

0.125

|

0.144

|

0.176

|

-

|

-

|

-

|

-

|

-

|

|

9.52

|

0.112

|

0.134

|

0.154

|

0.174

|

0.213

|

0.249

|

0.317

|

-

|

-

|

-

|

-

|

-

|

|

10.0

|

0.119

|

0.141

|

0.163

|

0.184

|

0.225

|

0.264

|

0.336

|

-

|

-

|

-

|

-

|

-

|

|

12.7

|

0.153

|

0.182

|

0.210

|

0.238

|

0.293

|

0.345

|

0.444

|

-

|

-

|

-

|

-

|

-

|

|

14.0

|

0.169

|

0.201

|

0.233

|

0.264

|

0.325

|

0.384

|

0.496

|

-

|

-

|

-

|

-

|

-

|

|

15.87

|

0.192

|

0.229

|

0.266

|

0.301

|

0.372

|

0.440

|

0.571

|

0.694

|

-

|

-

|

-

|

-

|

|

19.0

|

0.231

|

0.276

|

0.320

|

0.364

|

0.450

|

0.534

|

0.696

|

0.850

|

1.066

|

1.200

|

1.264

|

-

|

|

25.0

|

0.306

|

0.366

|

0.425

|

0.484

|

0.600

|

0.714

|

0.936

|

1.150

|

1.456

|

1.650

|

1.744

|

1.926

|

|

25.4

|

0.311

|

0.372

|

0.432

|

0.492

|

0.610

|

0.726

|

0.952

|

1.170

|

1.482

|

1.680

|

1.776

|

1.962

|

|

31.8

|

-

|

-

|

-

|

-

|

-

|

0.918

|

1.208

|

1.490

|

1.898

|

2.160

|

2.288

|

2.538

|

|

38.0

|

-

|

-

|

-

|

-

|

-

|

1.104

|

1.456

|

1.800

|

2.301

|

2.625

|

2.784

|

3.096

|

|

44.5

|

-

|

-

|

-

|

-

|

-

|

1.299

|

1.716

|

2.125

|

2.724

|

3.113

|

3.304

|

3.681

|

|

50.8

|

-

|

-

|

-

|

-

|

-

|

1.488

|

1.968

|

2.440

|

3.133

|

3.585

|

3.808

|

4.248

|

|

63.5

|

-

|

-

|

-

|

-

|

-

|

-

|

2.476

|

3.075

|

3.959

|

4.538

|

4.824

|

5.391

|

|

76.1

|

-

|

-

|

-

|

-

|

-

|

-

|

2.980

|

3.705

|

4.778

|

5.483

|

5.832

|

6.525

|

|

101.6

|

-

|

-

|

-

|

-

|

-

|

-

|

4.000

|

4.980

|

6.435

|

7.395

|

7.872

|

8.820

|

Tubular Heaters | Cartridge Heaters | Band Heaters | Strip Heaters | Cast-in Heaters

| Water

Heaters | Component Heaters | Immersion

Heaters | Circulation Heaters |

| Process Heaters | Canteen

Equipments | Control Panels | Thermostats

|S.S. Tubes | Appliances

|

Site

Best Viewed 800 x 600 Pixels IE -5 & above

Web Developers

SPRINT INFOTECH LTD.